In recent years, 3D printing has become a key tool in engineering. It helps engineers create designs fast and with less cost. This article will explain how 3D printing is changing engineering in many ways.

What Is 3D Printing?

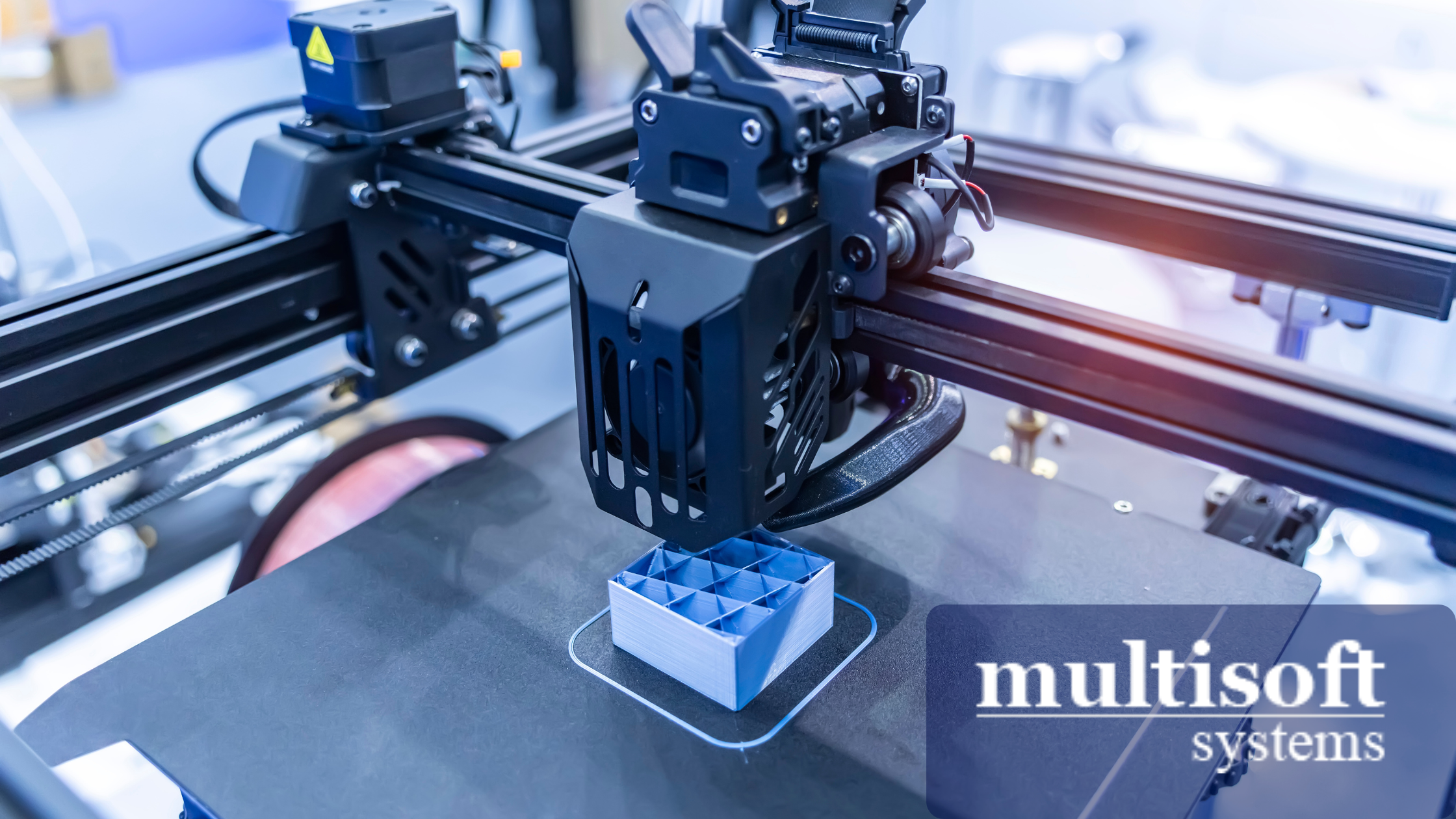

3D printing is a way to make real objects from digital designs. A machine builds the object layer by layer. It uses materials like plastic, metal, or resin. This process is also called additive manufacturing.

Before 3D printing, engineers had to use molds or cut parts from big blocks. These ways took more time and money. Now, 3D printing makes creating parts easier and faster.

Credit: amfg.ai

Design Freedom

One big change 3D printing brings is design freedom. Engineers can make shapes that were hard or impossible before. Complex parts with many curves or hollow spaces can be made easily.

For example, parts with internal channels for cooling or lightweight structures with strong support are now possible. This freedom helps engineers build better machines and tools.

Rapid Prototyping

3D printing helps engineers test ideas quickly. They can print a part in hours, not days or weeks. This fast process is called rapid prototyping.

Rapid prototyping lets engineers see and touch their designs. They can find problems and fix them fast. This saves time and money in product development.

Before 3D printing, prototypes were expensive and slow to make. Now, engineers can make many versions quickly and choose the best one.

Cost Reduction

3D printing can reduce costs in many ways. It uses only the material needed for the part. This is different from cutting or molding, which wastes more material.

Also, 3D printers can work in small batches. There is no need to make large quantities to reduce cost. This helps small companies and startups create parts without big investment.

Engineers save money on tools and molds too. These are often expensive in traditional manufacturing.

Customization

3D printing allows easy customization of parts. Engineers can change a design quickly for different needs. For example, medical engineers print custom implants that fit each patient perfectly.

Customization is useful in many fields like automotive, aerospace, and consumer products. It helps make better products for specific uses.

Material Variety

3D printing uses many materials today. Plastic is common and cheap. Engineers also print with metals like aluminum and titanium. These metals are strong and light.

New materials are being developed, such as flexible plastics and ceramics. This variety allows engineers to choose the best material for each part.

Impact on Manufacturing

3D printing changes how engineers make products. It supports small production runs and one-of-a-kind parts. This is different from mass production, which makes many identical items.

Manufacturing can be closer to the customer. Parts can be printed on-site or nearby. This reduces shipping costs and time.

Also, 3D printing can make parts with fewer assembly steps. Complex parts can be printed as one piece, saving time and effort.

Credit: www.multisoftsystems.com

Environmental Benefits

3D printing can be better for the environment. It creates less waste because it uses only needed material. Traditional methods often cut away extra material.

Some 3D printers use recycled materials. This helps reduce plastic waste. Also, printing parts locally lowers carbon emissions from transport.

Challenges of 3D Printing

Though 3D printing helps a lot, it has limits. Printing large parts can take many hours or days. Some materials are still expensive or hard to print.

Surface finish and strength might not match traditional methods yet. Engineers must choose when to use 3D printing carefully.

Examples of 3D Printing in Engineering

Here are some ways 3D printing is used in engineering today:

- Aerospace: Printing lightweight parts saves fuel and cost.

- Automotive: Making custom parts and prototypes fast.

- Medical: Custom implants and surgical tools.

- Construction: Printing building components and models.

- Robotics: Creating complex parts for robots quickly.

How Engineers Use 3D Printing Today

Many engineers use 3D printing every day. They design parts on computers and print them in the office or lab. They test new ideas fast and improve designs step by step.

Some companies have small printers for plastic parts. Others use big printers for metal parts. Prices of printers are going down, making them more common.

Future of 3D Printing in Engineering

The future looks bright for 3D printing in engineering. New materials and faster printers are being developed. More engineers will use 3D printing to solve problems.

We may see 3D printers on job sites or in factories everywhere. This will help make products better and faster.

Summary Table: Benefits of 3D Printing in Engineering

| Benefit | Description |

|---|---|

| Design Freedom | Create complex shapes and lightweight parts easily. |

| Rapid Prototyping | Print parts quickly to test and improve designs. |

| Cost Reduction | Use only needed materials and avoid expensive molds. |

| Customization | Make parts tailored for specific needs or people. |

| Material Variety | Use plastics, metals, and new materials for parts. |

| Environmental Benefits | Less waste and lower carbon emissions from transport. |

Frequently Asked Questions

What Is 3d Printing In Engineering?

3D printing builds objects layer by layer from digital designs. It allows precise and fast creation of engineering parts.

How Does 3d Printing Speed Up Prototyping?

3D printing creates prototypes in hours, not days or weeks. This helps engineers test and improve designs quickly.

Can 3d Printing Reduce Engineering Costs?

Yes, 3D printing lowers costs by using less material and cutting production time. It avoids expensive tooling and waste.

What Materials Are Used In 3d Printing For Engineering?

Common materials include plastic filaments like ABS and metal powders. Choices depend on the part’s function and strength needs.

Conclusion

3D printing is changing engineering in many ways. It helps engineers design better, build faster, and spend less. It gives more freedom to create new ideas and products.

Though there are some challenges, the benefits are strong. As technology grows, 3D printing will become even more useful in engineering.

For anyone interested in how things are made, 3D printing is an exciting tool to watch and learn about.